Flexible conveying spirals are particularly low-maintenance and are therefore preferred by the industry for durable conveyor systems. Steiner spirals equips industrial conveyor systems with its flexible spirals. Whether it is in the Timber industry wood chips, sawdust, sanding dust & wood waste to be conveyed or the Food industry sensitive materials such as coffee, sugar or baking agents are transported through the production line with a conveyor system, the conveyor systems from Steiner spirals are convincing. Also the Plastics industry relies on the flexible spiral conveyors from Kirchdorf am Inn for conveying PVC pellets, PVC powder and plastic granulate.

Our conveyor systems with flexible spirals are equipped with a Conveying capacity from 0.09m³/h to 8 m³/h available.

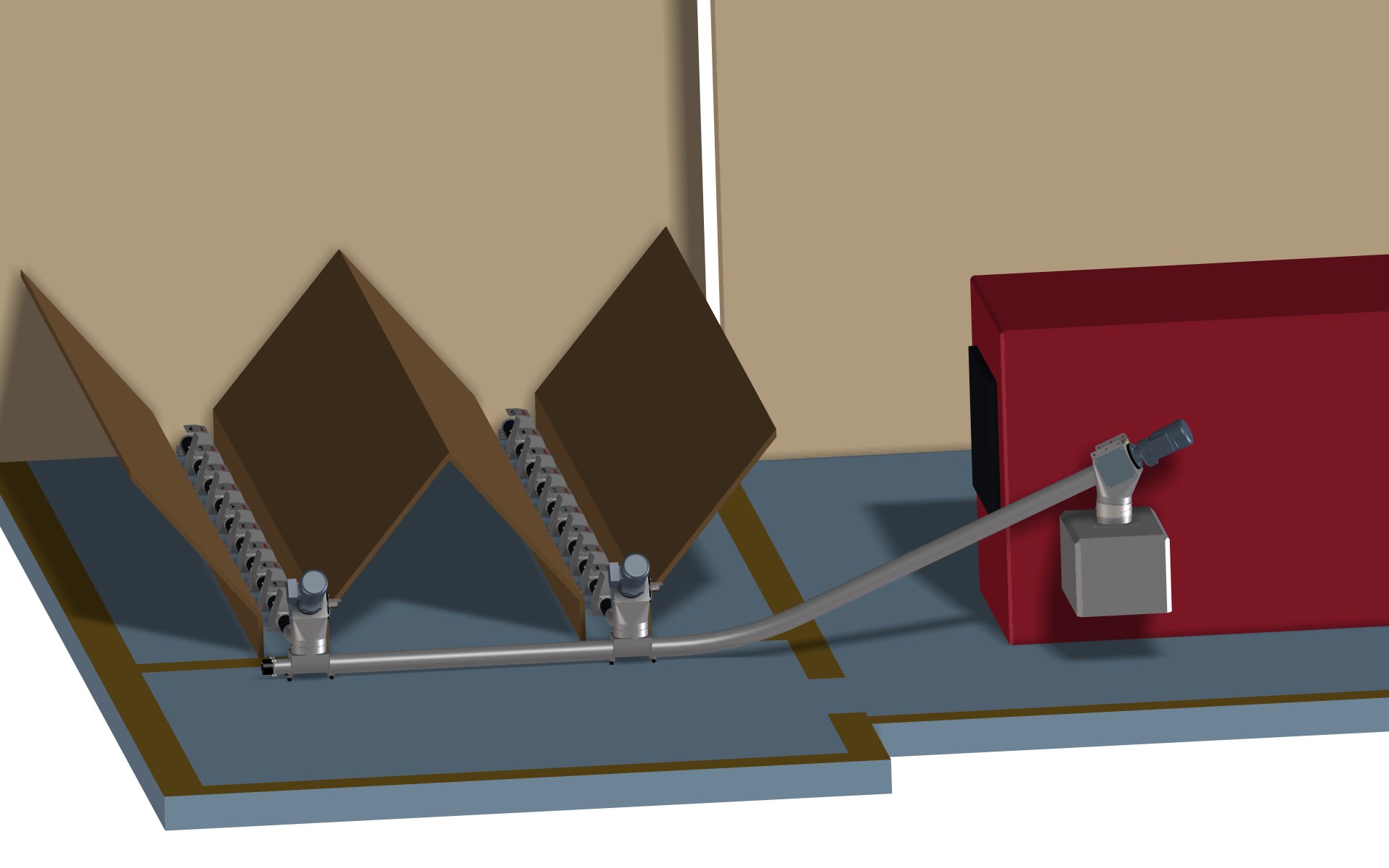

Flexible spiral conveyors from Steiner: low maintenance & durable

The flexible spirals for conveyor systems from Steiner spirals are characterized in particular by low maintenance off. Through the cuddly movement of the spiral and the absence of corners, gears or chains the system is practically maintenance-free. A factor that is especially important in the industrial environment. To keep plant downtimes as low as possible, the use of our flexible spiral conveyors is definitely recommended for suitable bulk materials. For 30 years, Steiner spirals has stood for the highest quality. The flexible spirals are made of specially hardened steel manufactured and are characterized by high tensile strength and spring force. Besides a long service life this structure also enables various media to be in curves and gradients, horizontal and vertical to promote.

Advantages of flexible spiral conveyors:

- Dust-free transport on curves and inclines

- Low noise

- Economic in energy consumption

- Reliable and durable

- Design of the conveyor system to meet individual requirements

Drive unit- energy efficient conveying systems from Steiner

The Drive unit is optionally equipped with Gear or frequency controlled motor. Depending on the spiral type and medium, as well as the required conveying capacity per hour, motors are used accordingly. This results in a Maximum output at minimal energy consumption. For many years, Steiner spirals has been focusing on drive concepts which are as enable energy-efficient conveyor systems .

Intake Station & Procedures:

Receiving hoppers for the conveying system are available in various designs, each matched to the pumped medium and the storage tank. Drains can be attached to the conveying pipe in any number. Mechanical or automatic gate valves enable the pumped medium to be discharged from the conveying system in a targeted manner.

Technical data on flexible spirals from Steiner spirals

- Wood industry, e.g. wood chips, sawdust, sanding dust, wood waste, etc.

- Food industry, e.g. salt, sugar, coffee beans, etc.

- Plastic industry, e.g. PVC pellets, PVC powder, plastic granules, etc.

- Others like gravel, styrofoam, washing powder etc.

Available in different sizes: 0.09 m³/h to 8 m³/h