Conveyor spirals tailor-made for recycled material

The transport of recycling material poses special challenges for the conveyor technology used. Unlike the conveying of raw materials in the industrial production process and homogeneous material, such as granules or pellets, conveying spirals for recycled material have to cope with goods of very different properties. In addition, robustness against environmental influences must not be underestimated as a decisive factor for the longevity of the entire conveyor systems.

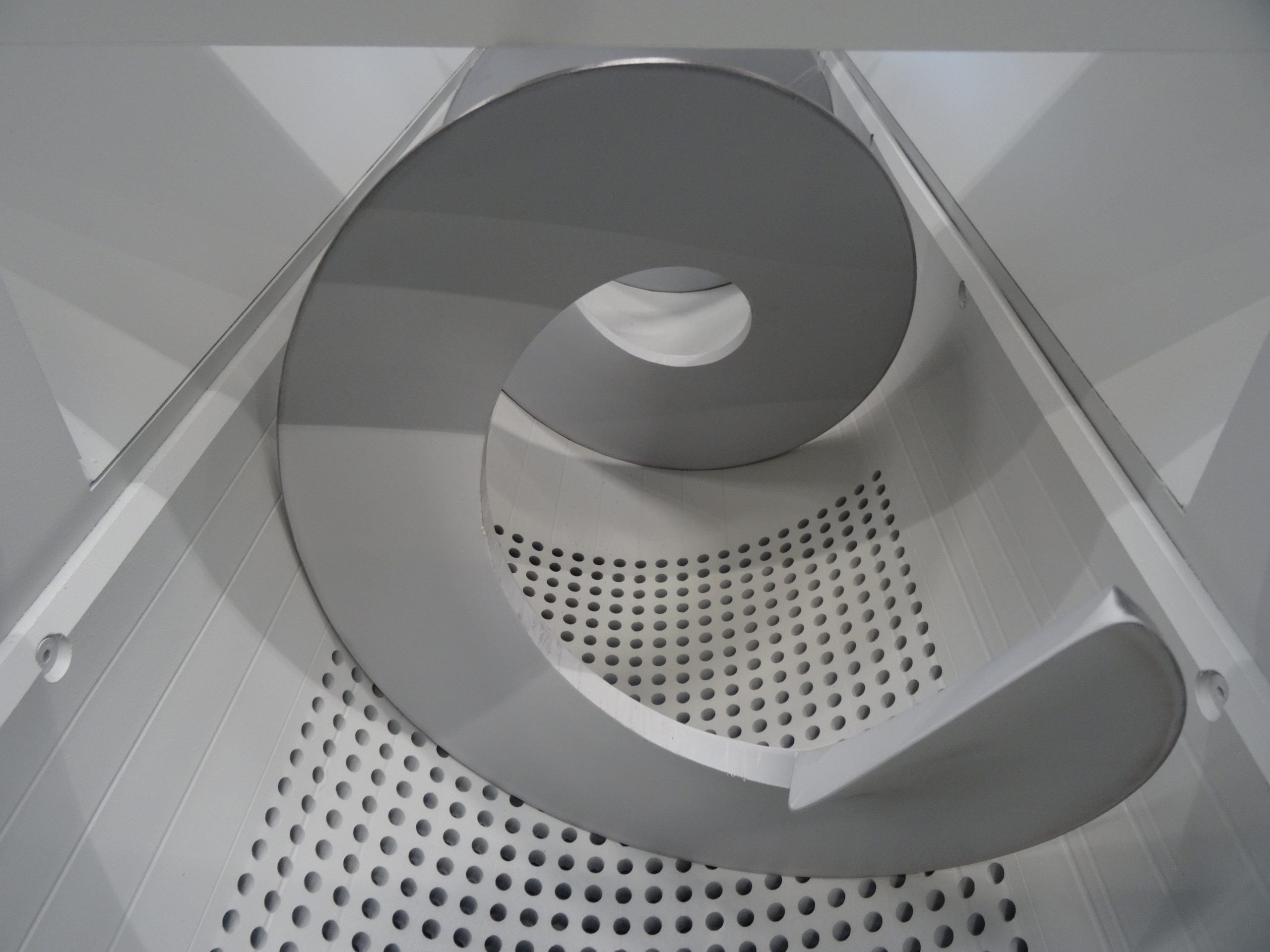

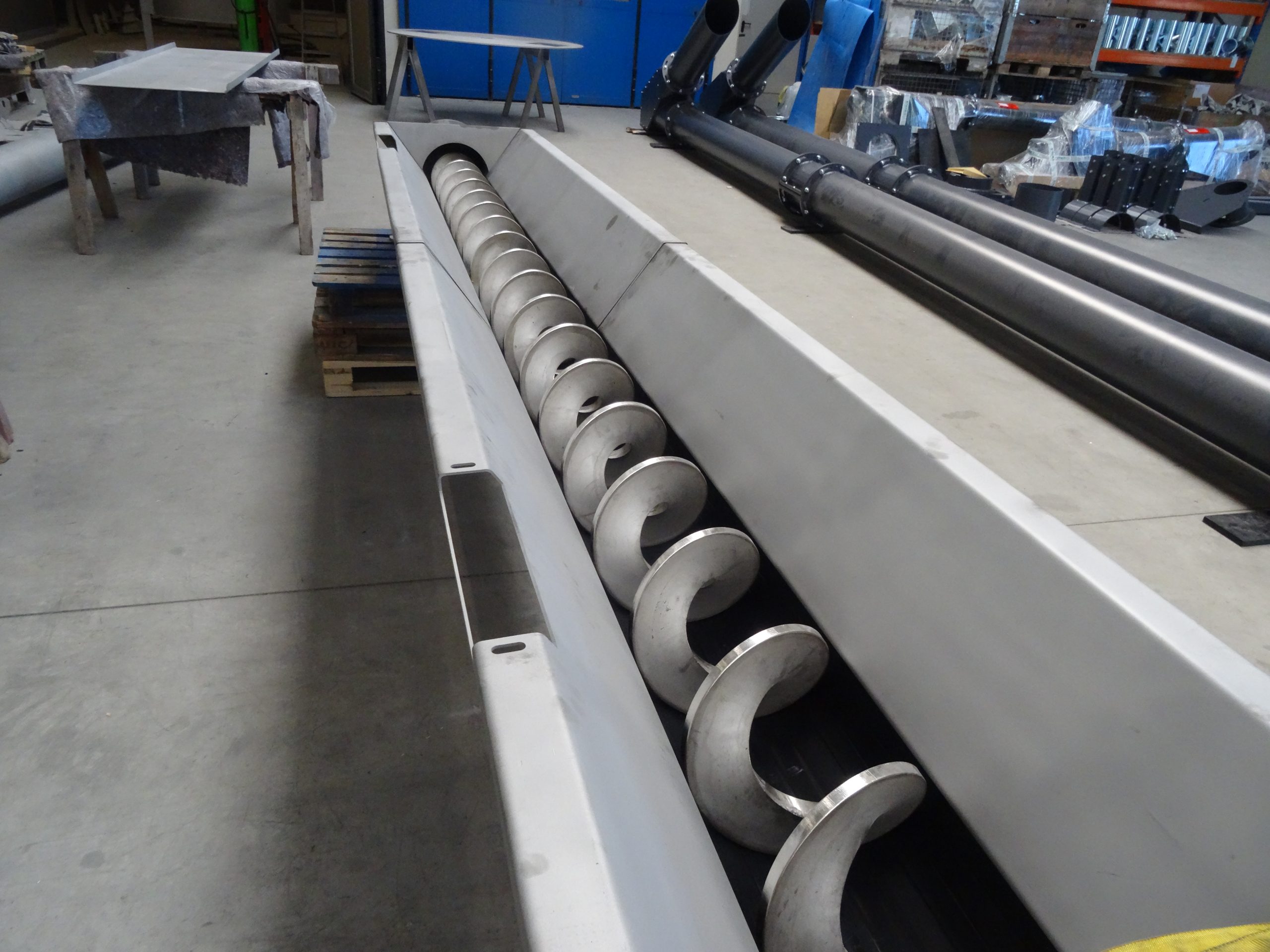

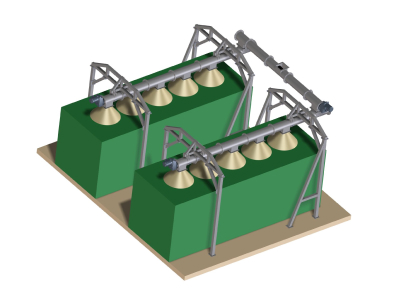

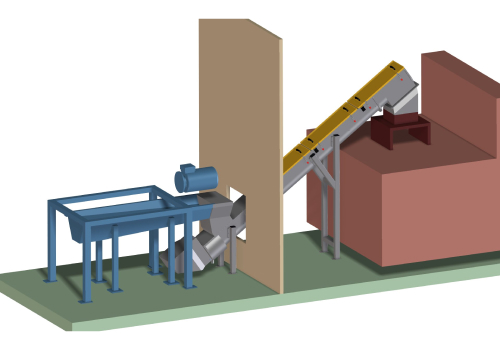

Steiner’s shaftless conveying spirals meet these conditions perfectly. Depending on the application, rigid or flexible conveying spirals are used.

Rigid conveying spirals made of steel primarily convey coarse-grained recycling material (part lengths up to 200 mm) and are also ideally suited for vertical conveying systems. Even a long conveying distance (up to 30 m without intermediate storage) is best realized with steel spirals.

Flexible conveying spirals made of steel are enormously low-maintenance and capable of transporting conveyed material in curves and over corners.

However, both variants have one decisive advantage in common: The absence of center shafts makes it possible to transport particularly heterogeneous material. This prevents jamming even with large-particle and long-fibered conveyed material and ensures fluid transport.

Advantages of Steiner conveyor spirals for recycled material

- different grain size of the material to be conveyed

- different Consistency of the material

- different size of the components to be conveyed

- optimal conveying of long-fiber materials

- moist and wet material

- Residues of oil and other problem materials

With Steiner spirals, your conveyor systems are designed individually and project-related. Regardless of whether it is the transport of problematic materials, sewage sludge or materials of difficult consistency, Steiner spirals will find the optimal solution.

Especially in the field of recycling, new and individual requirements for a conveyor system arise again and again, which cannot be covered by standard solutions. Material contaminated with oil, sealed containers with contents, material with specific viscosity, the challenges for a conveying system are manifold and always new, especially for recycling materials.

For this reason, especially in this segment, conducting conveying trials is often a viable way to test the feasibility of concepts for the most efficient transport of your materials. The team at Steiner is also tried and tested in conducting these tests over many years.