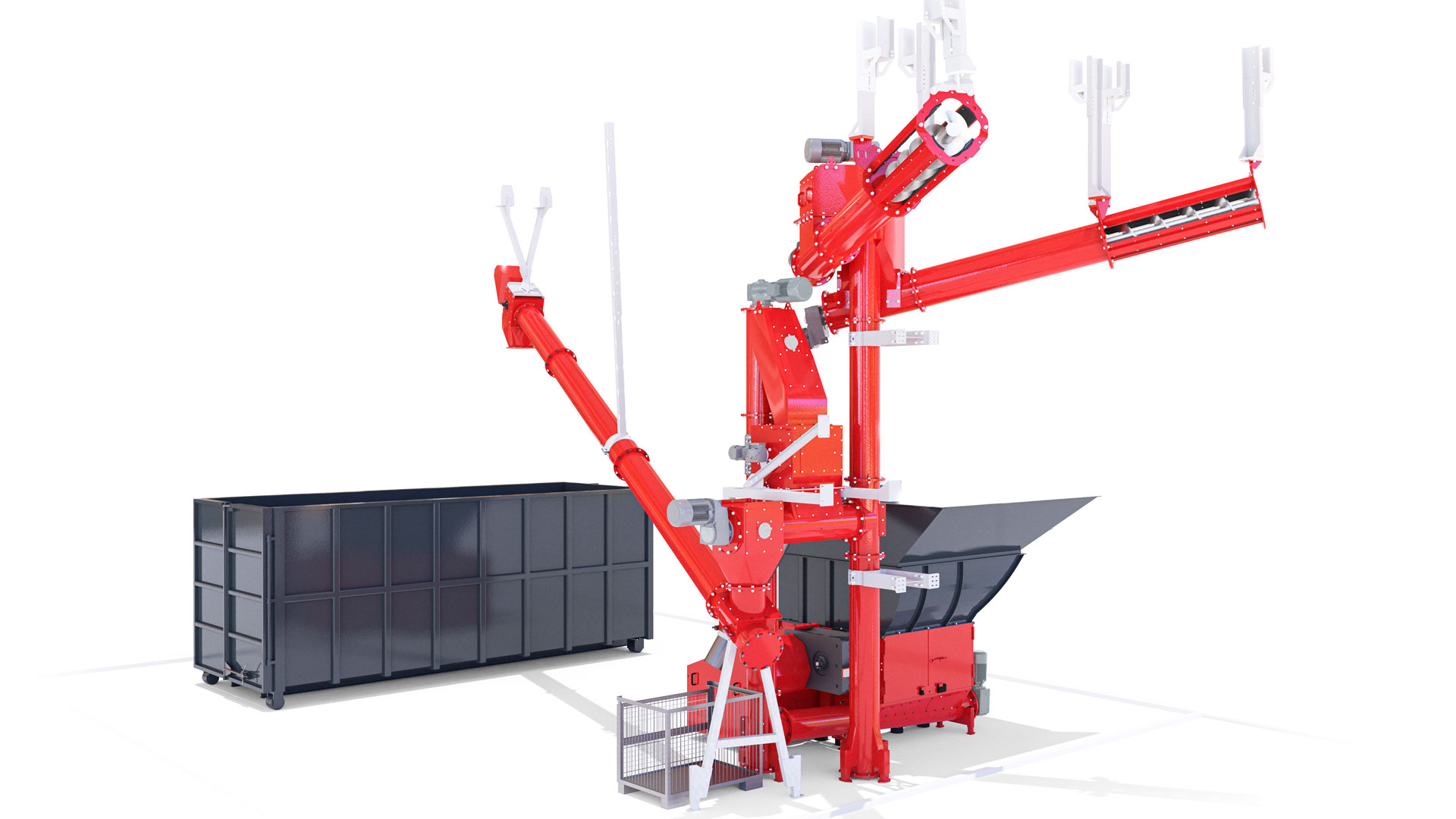

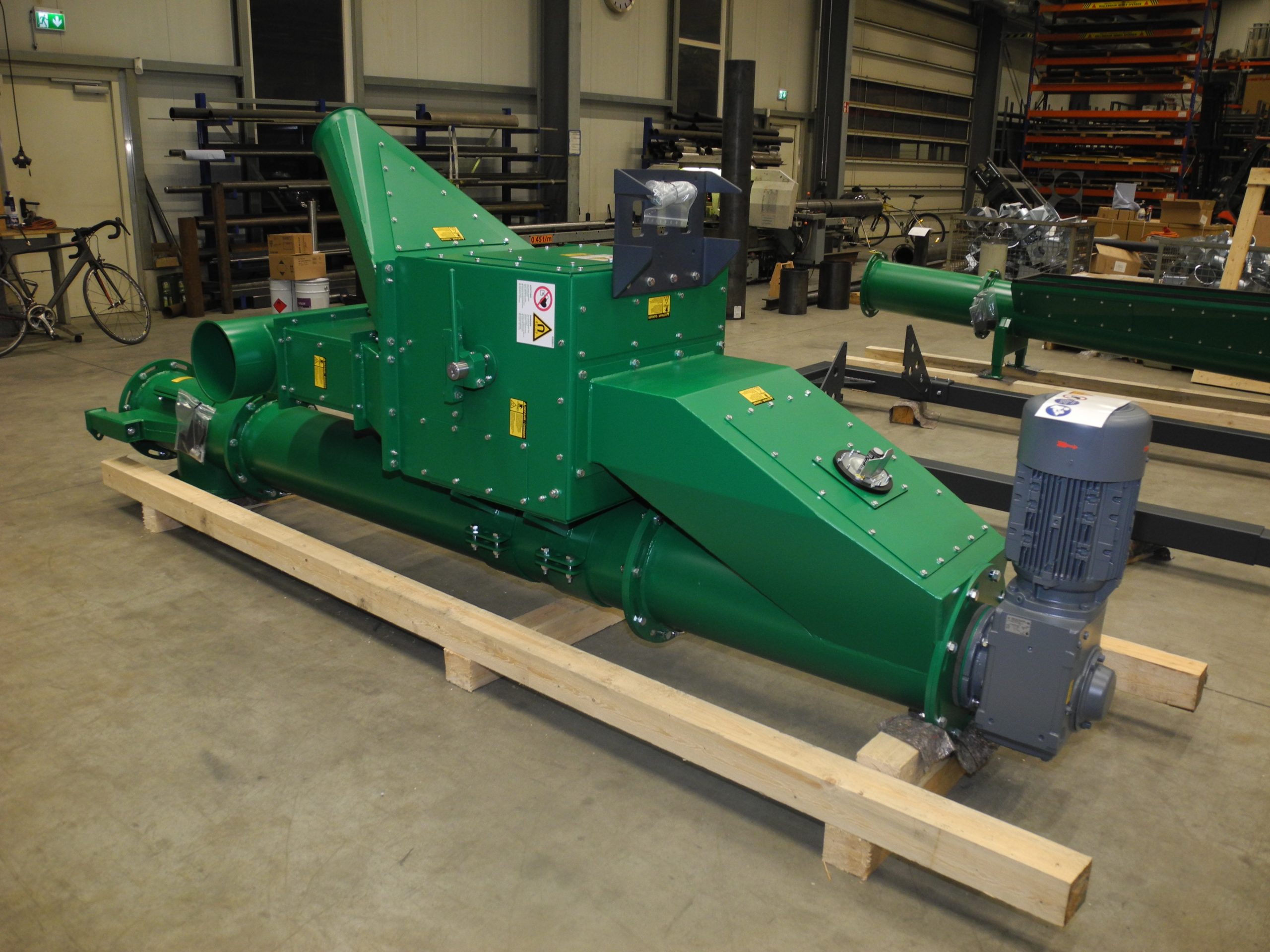

As your partner for tailor-made conveyor systems Steiner GmbH & Co KG from Kirchdorf am Inn your specific requirements when conveying biomass. Achieve efficiency in the design of conveyor systems in modular construction and in exact coordination with the conveying quantities, the conveying path and the nature of your material to be conveyed. In the case of biomass, the gentle transport of large quantities of material is often required.

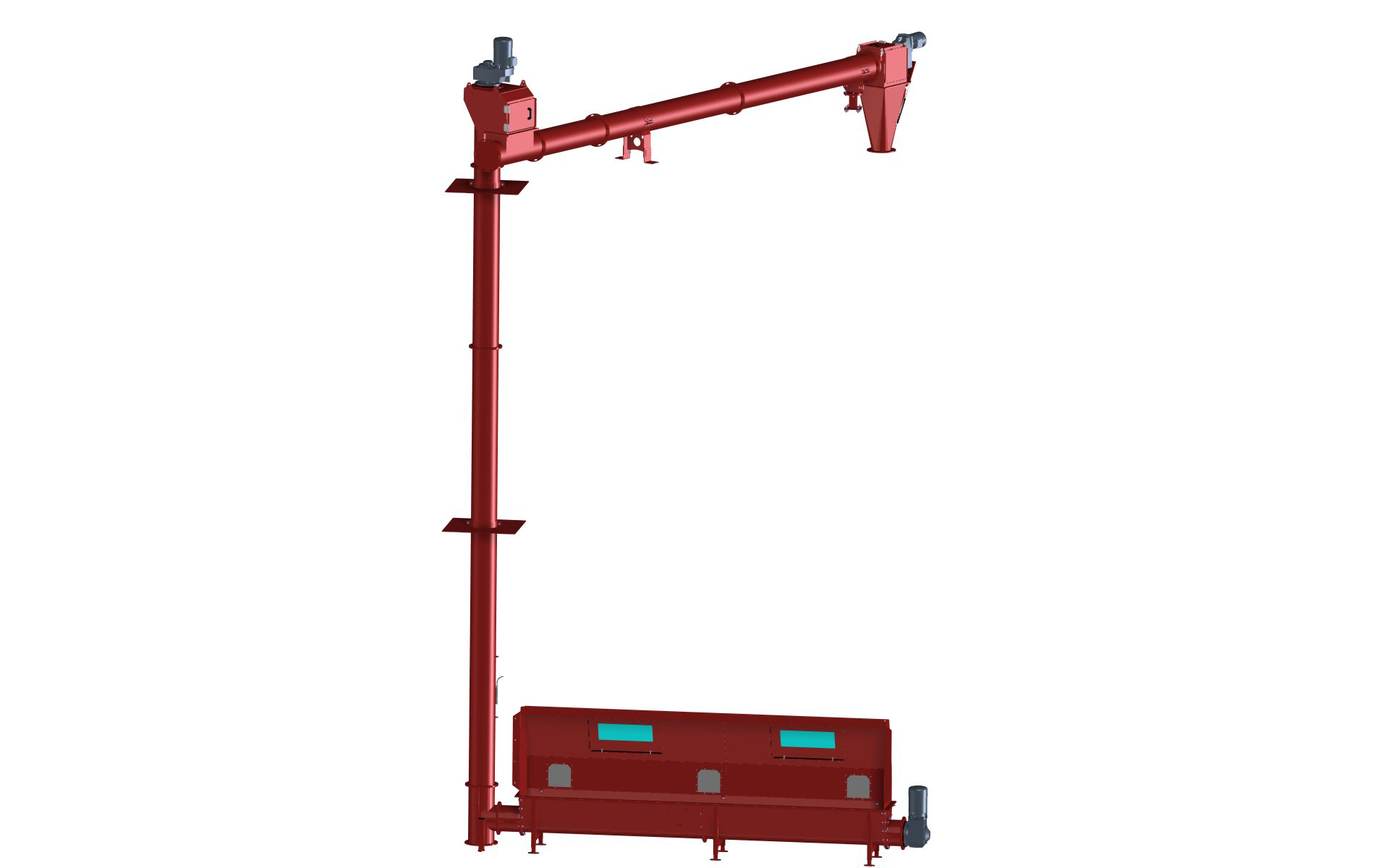

Depending on the specific profile of requirements, a rigid or flexible Conveyor spiral made of steel are used. In any case, the shaftless Conveyor spiral a variety of advantages.

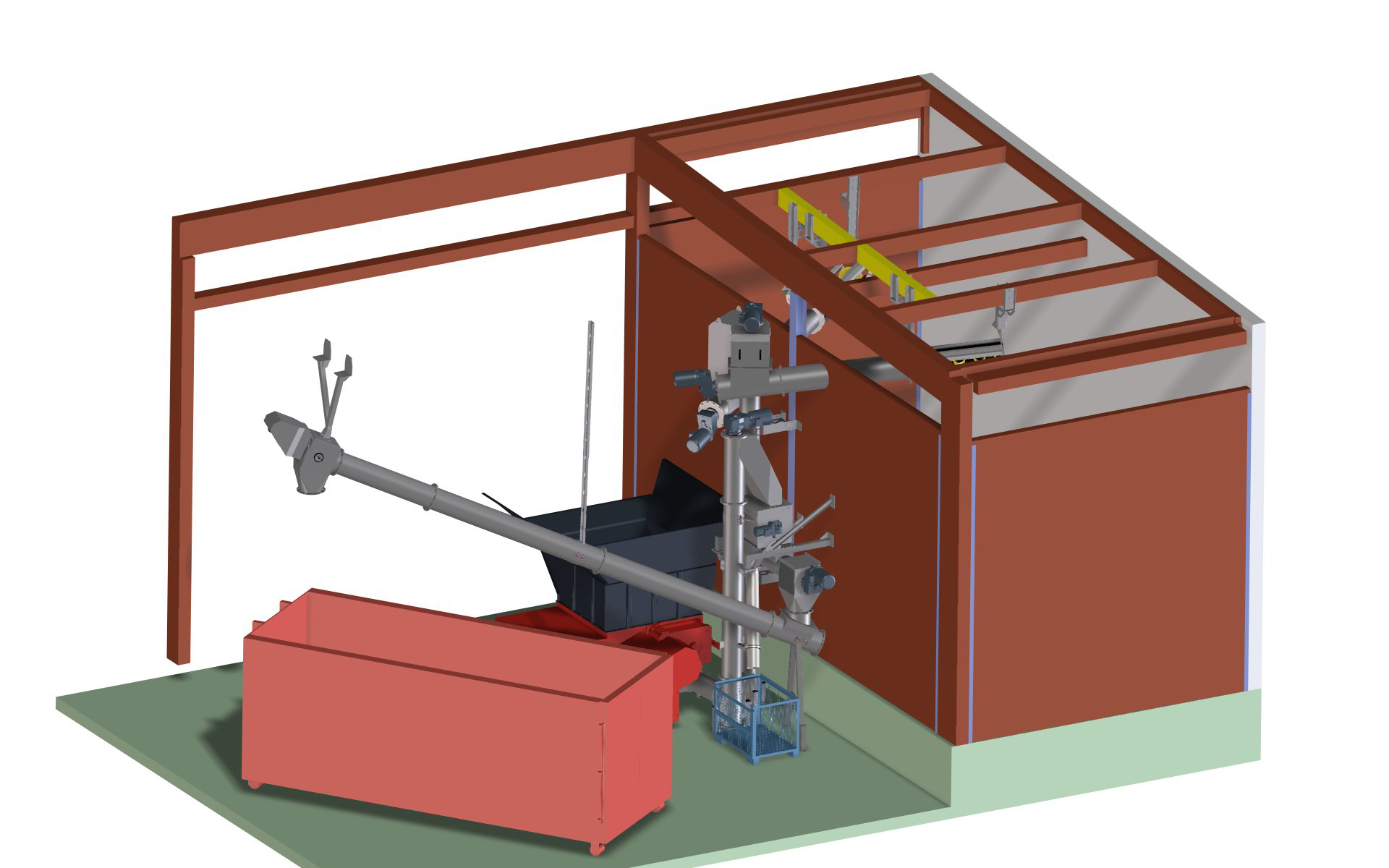

Steiner spiral conveyor systems as a partner for individual solutions

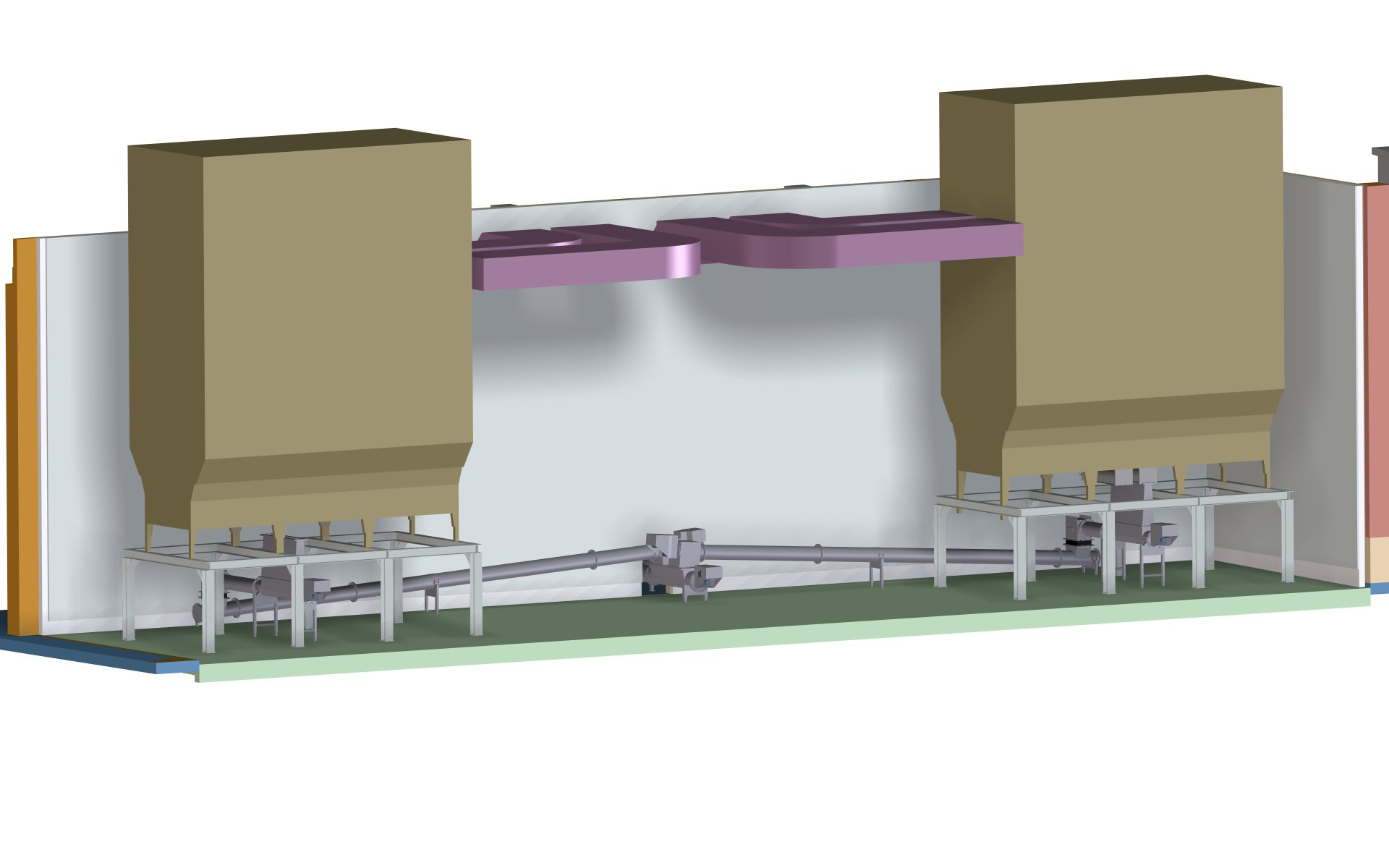

Steiner Spiralen is your reliable partner for the planning and implementation of biomass plants, even for challenges such as wall and ceiling penetrations.

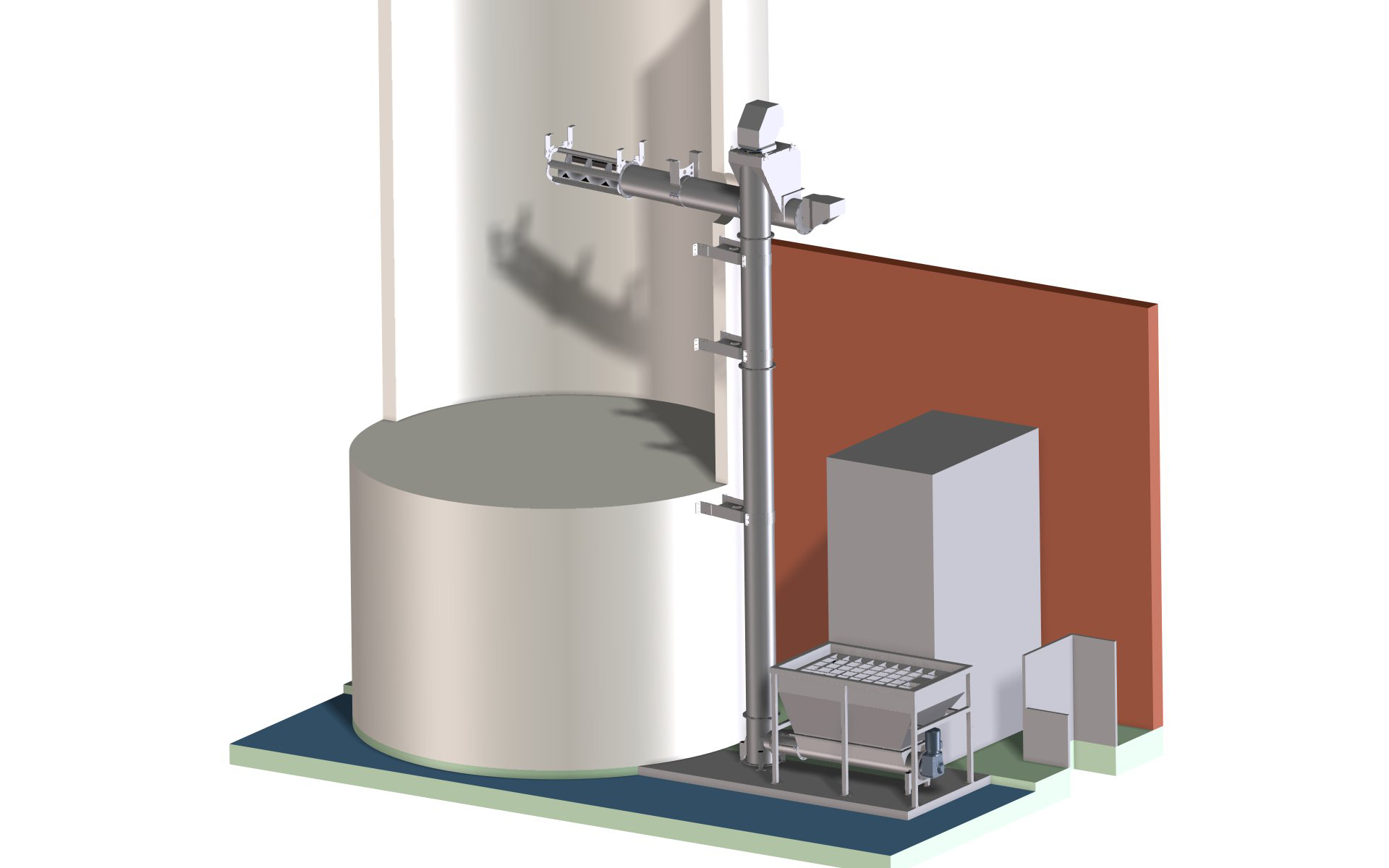

Heating material made of wood makes ecological and economic sense. Ensure low-maintenance efficient overall systems with the optimally matched conveyor system for your heating systems, whether pellets or wood chips.

Steiner Spiralen pays attention to full compatibility with existing plants and designs solutions for silos, bunkers, containers and all other types of components. Let us know your special requirements – we look forward to your inquiry!