A Pellet heating is the perfect heating solution from renewable energy for many homeowners but also businesses. The raw material wood as the basic material for pellets is CO2 neutral and thus a heating material that really can be used sustainably . This is good for the environment and for the next generations. Federal and state incentive loans and grants have also given pellet heating a further boost. For many years, heating with pellets has been considered a good solution for sustainable energy at home.

Conveying pellets – from the storage room to the boiler

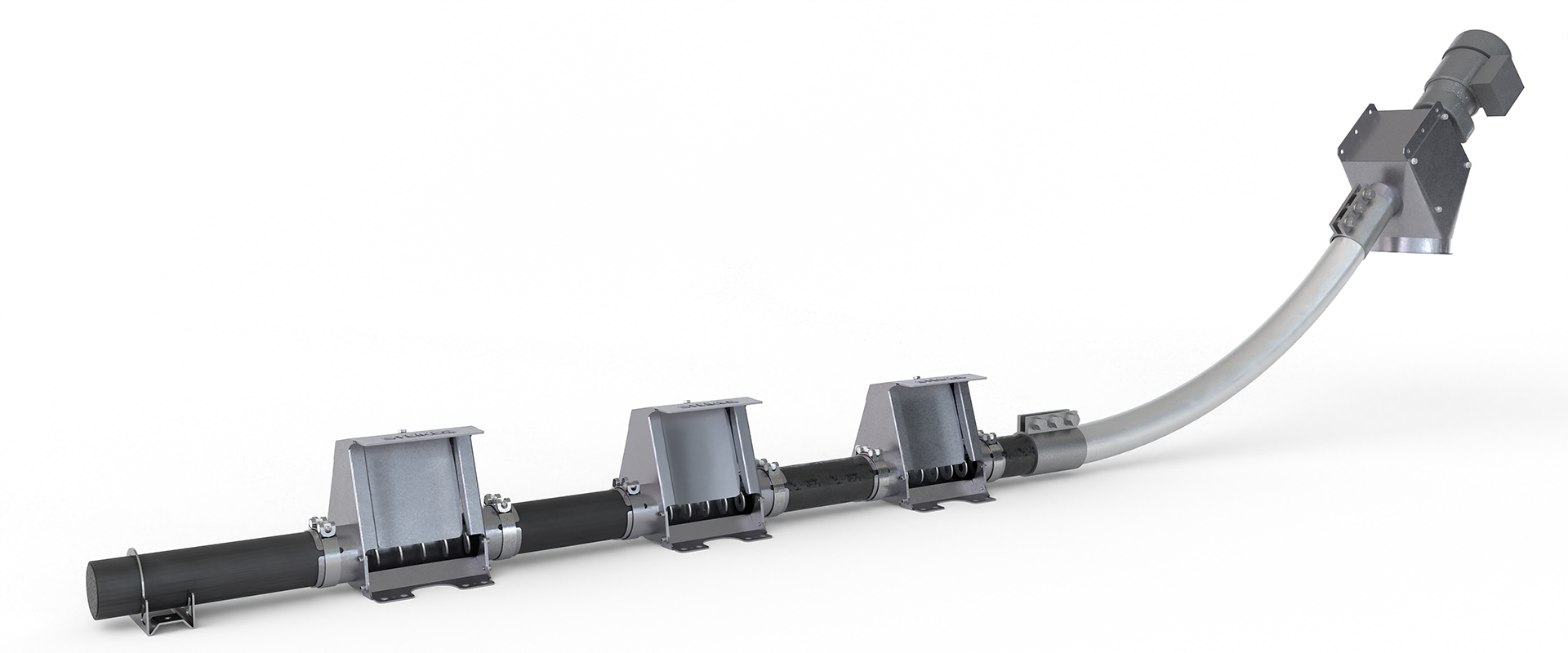

With wood pellets as a heating material, the following questions always arise despite all the euphoria: How to store the pellets? How to convey the pellets? Often a classic standard [Pelletfördersystem](/foerderanlagen/) is sufficient, as Steiner Spiralen has been successfully manufacturing and selling for many years. Sometimes, however, individual solutions are required to overcome long conveying distances or large differences in height. Whether vertical or horizontal conveying of pellets – Steiner Spiralen has the solution! Regardless of the conveying volume and the conveying distances over which you need to convey pellets: Steiner Spiralen is guaranteed to have the right conveying system. We offer our pellet conveying solutions for resellers such as installers, plumbers & heating engineers, as well as for private customers.

Steiner – A reliable partner in planning your pellet project

Steiner Spiralen thus supports its customers and partners with both standard solutions and individual concepts and projects. Especially in the medium and large boiler sector, customized project planning is recommended in order to obtain low-maintenance, non-fault-prone and energy-efficient systems.

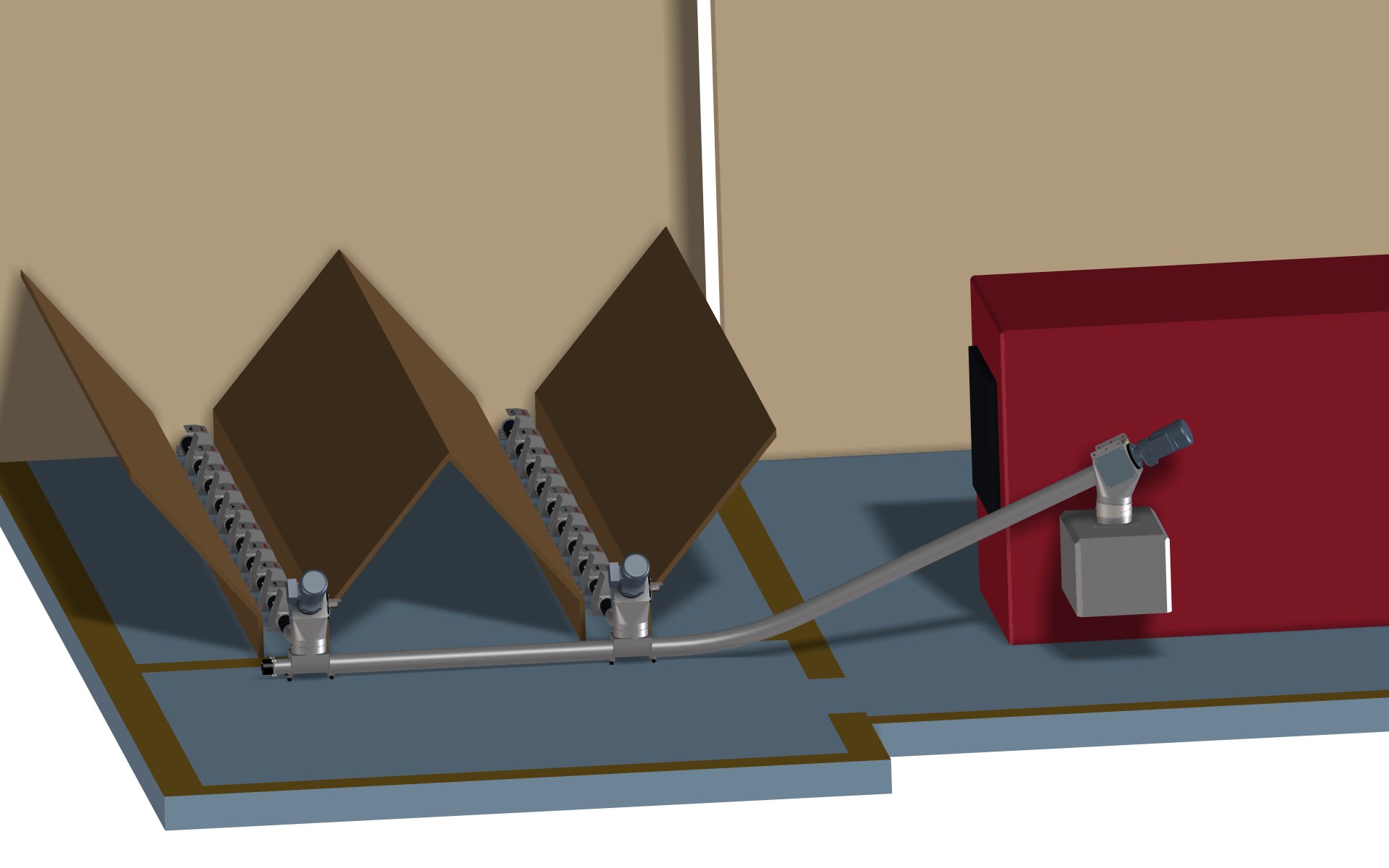

Based on your plan sections or hand sketches, Steiner Spiralen projects your pellet conveyor system. This ranges from a conveyor line directly onto the boiler, to complex plants with 4 to 6 hopper lines and cross conveyor spirals of up to 60 m across the building. Differences in height between the storage room and boiler room of up to 20 m are feasible for the experts from the district of Rottal am Inn. Storage rooms with 8 m filling height do not cause any problems. This wide range of possibilities provides alternatives to round discharges and push floors. The systems can also be combined with exhaust systems.

The planning department at Steiner Spiralen in Kirchdorf then designs 3D models that can be incorporated into the existing building services planning. Based on this free planning, binding and free offers are prepared.

The Steiner Spiralen team will advise you on all individual challenges, such as any necessary wall and ceiling penetrations, use of underground parking areas and much more. The experts from Kirchdorf am Inn have decades of experience in designing customized solutions.

Conveyor systems from Steiner – the right solution for every project

Various options are available for material transfer:

- Single intake hopper in pellet bunker

- Receiving hopper for silos / bag silos

- U troughs for bag silos