We offer both flexible and rigid discharge systems for stationary shredders. With both systems, we can pick up the material directly from under the shredder and transport it to the desired discharge point.

Depending on the requirements, we use either rigid or flexible spirals. In addition, these discharge systems can be combined with magnetic separators or intermediate outlets to meet specific needs.

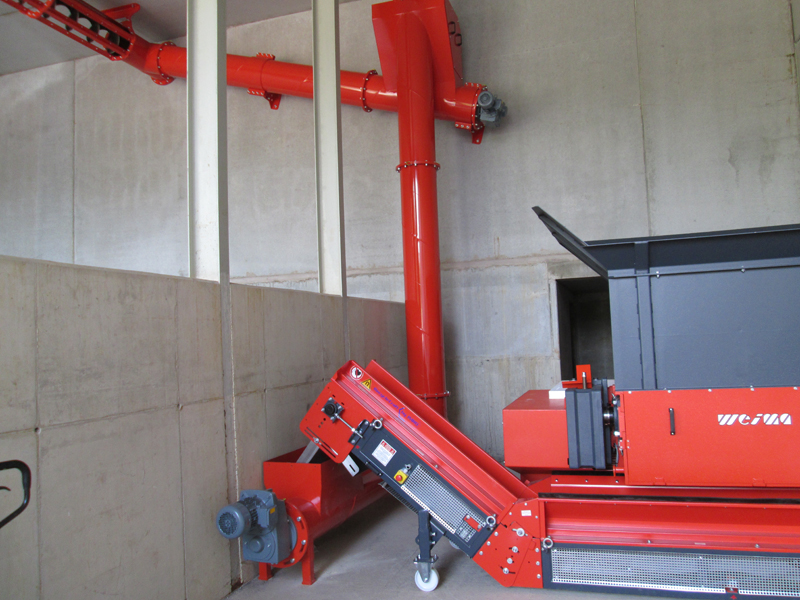

Shredder discharge with flexible conveyor system

Up to a screen size of 20 mm, our flexible conveyor system can be used for shredder discharge.

- Conveyor pipe in stainless steel or metal

- Shredder internals are made to measure depending on the shredder type

- Different line layouts possible

- Combination with FE parts separator possible

- Individual planning according to customer requirements

- Support from planning to commissioning

- CAD planning included

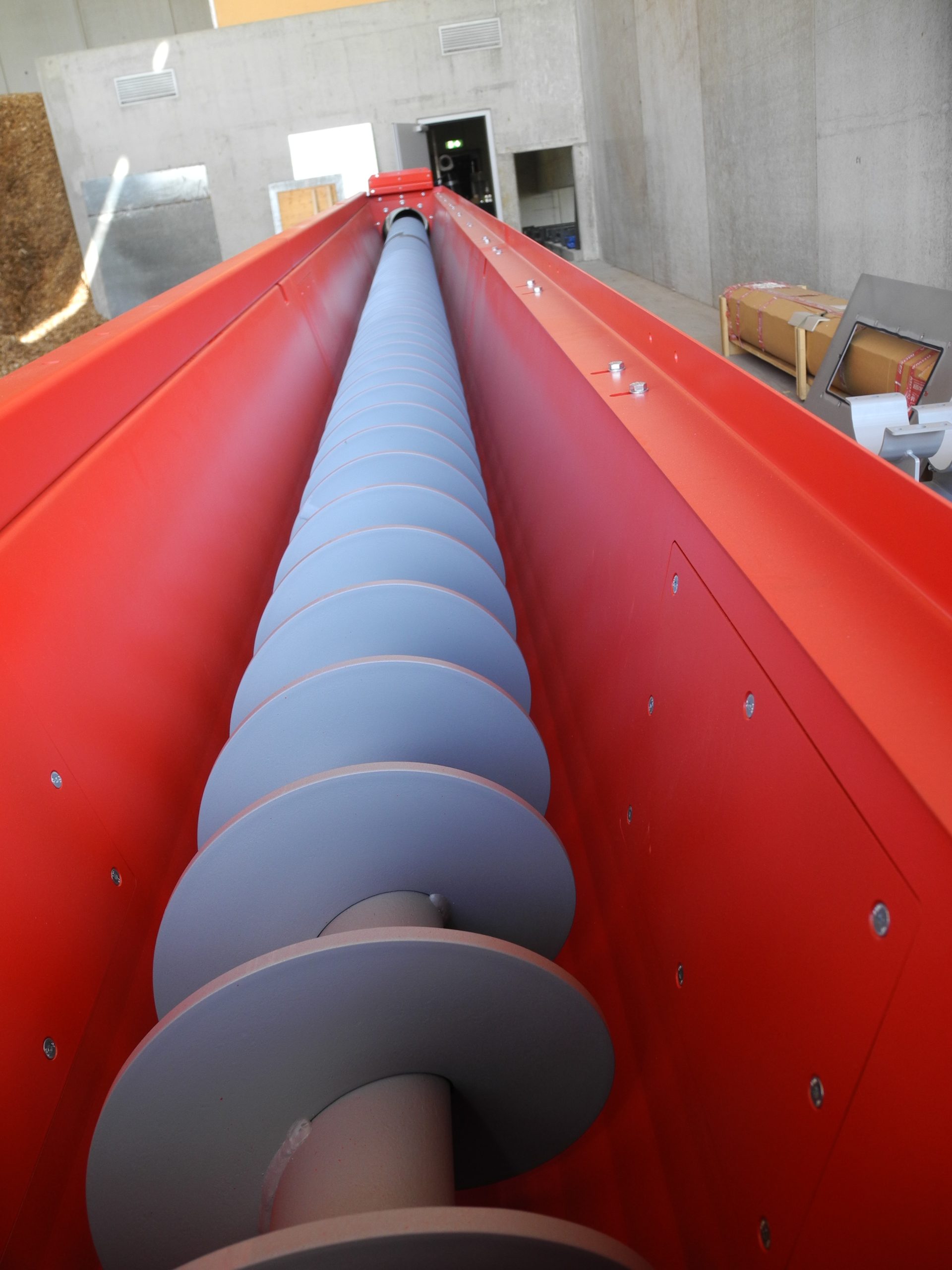

Shredder straining with rigid conveyor system

From a shredder screen size of 25 mm, we use our SG rigid Conveyor System. We take care of the technical design for you.

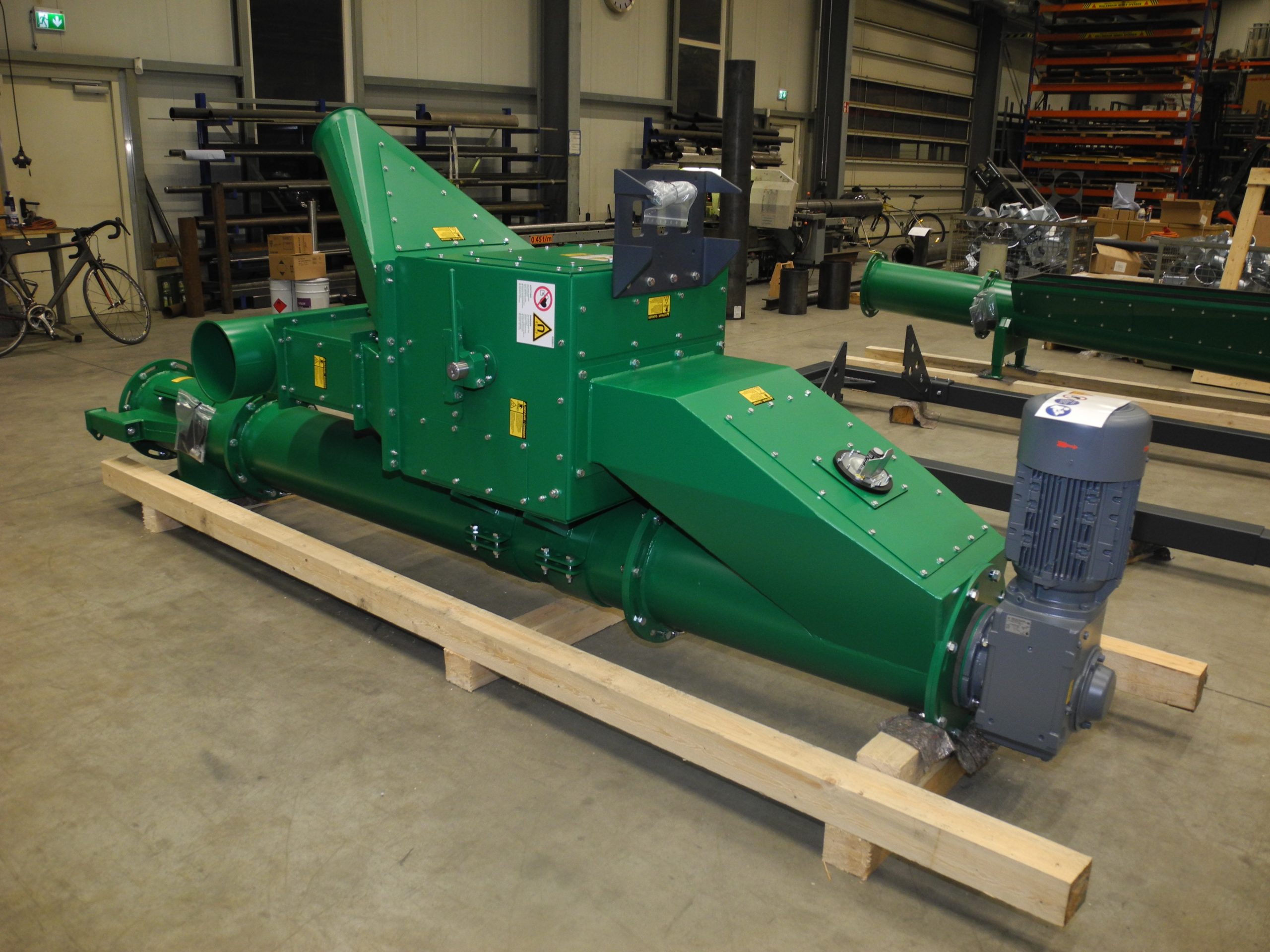

In the conveyor shown below you can see a shredder discharge in combination with a FE parts separator.

For example, wood chips and nails can be cleanly separated immediately during pallet shredding. The FE parts are collected in a collection container. For example, the wood chips are conveyed to a wood chip bunker.